As TCT Asia 2024 approaches, TCT has been talking to a number of the firms who’ve exhibited at every occasion all through its first ten years.

Materialise, a frontrunner in additive manufacturing software program and providers, is amongst these firms.

Right here, we speak to Materialise about what the corporate can be showcasing in Shanghai, how the Chinese language AM market is progressing, and what challenges the AM area nonetheless wants to beat.

Register to attend TCT Asia 2024 and go to Polymaker on sales space 8F61. TCT Asia runs from Could 7-9, 2024.

What’s Materialise presenting on the present flooring at TCT Asia 2024?

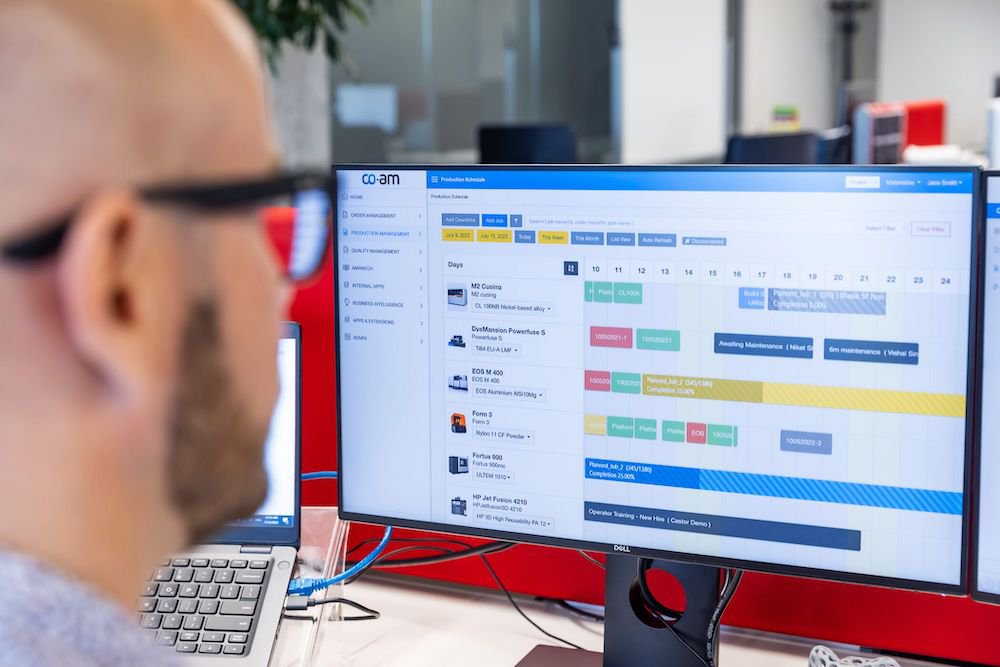

- Our whole software program resolution, together with main new updates of our Magics 3D Print suite from design to knowledge preparation, and the CO-AM platform.

- 3D printed elements/merchandise in numerous supplies and applied sciences, empowered by our software program options.

- VR expertise for Medical functions for visualisations.

- We can even have a full-day training session within the corridor for college college students on the primary day Could 7th.

Are you able to inform us about an thrilling utility that guests will be capable of see on the occasion?

Magics 28: The newest model of Magics (28) will launch on Could 15, however TCT Asia guests will get an unique preview. Magics is the software program of selection for big and sophisticated knowledge, and that is mirrored within the addition of beam lattice know-how in Magics. This not solely opens new design and printability alternatives, but in addition considerably hastens the workflow by working with lighter knowledge. We think about our customers’ wants and requests for each launch, so Magics is now quicker than ever and even features a darkish theme possibility. This enables customers to change to a darkish consumer interface, making a extra soothing consumer expertise. We additionally allow connectivity with different lattice design packages (through 3MF, mxp), exterior lattice Libraries equivalent to BASF and HP, and DfAM packages equivalent to nTop. Normal efficiency upgrades additionally embrace label planning enhancements that supply a pace improve of as much as 90% and a discount of reminiscence utilization of as much as 45%, relying on the scale of the half (the extra complicated the larger the achieve).

NxG Construct Processor: Previously 5 years, there was important progress in metallic 3D printing applied sciences as a result of rising buyer demand for printing bigger and extra complicated elements, leading to bigger information sizes. Consequently, quite a few OEMs have made substantial investments in creating bigger printers with expanded print volumes and elevated laser capability.

Materialise has responded by proactively upgrading their traditional BPs to assist 3D Printer OEMs speed up their growth cycle with off-the-shelf NxG BP, and with a customisable BP software program growth equipment (BP SDK) to fulfill buyer application-specific calls for. This empowers OEMs to harness Materialise’s 30+ years of AM experience by providing a complete suite of BP capabilities to enhance high quality, processing and manufacturing pace – tailor-made to swimsuit numerous AM applied sciences and particular functions with their very own assets or with the assist of our Providers Workforce.

TCT Asia is celebrating its tenth anniversary. What are your ideas on how the AM market, and particularly in China, has developed in that point?

5 years in the past, Materialise surveyed Chinese language manufacturing firms to gauge their curiosity and perspective towards 3D printing. The survey confirmed that China was largely centered on prototyping in its adoption of 3D printing and remained uncertain in regards to the readiness of the know-how for manufacturing ultimate merchandise. The truth is, Chinese language producers believed international adoption of 3D printing might even problem China’s place because the ‘manufacturing unit of the world’.

Quick ahead 5 years and it’s a really totally different image. Maybe much more so than in different areas, we’re seeing important developments in China. Prices are beneath management; new machines present high quality and effectivity at scale and inexpensive supplies make a lot bigger orders possible. We’re seeing large-scale functions equivalent to cell phone parts being produced in substantial volumes, and razor-thin titanium hinges for folding telephones, and the mass manufacturing of smartwatch instances. We’re speaking thousands and thousands of elements per 12 months.

Materialise lately launched its e-Stage for Steel+ software program to automate assist era for metallic 3D printing – What are the most important challenges it will clear up for producers?

For Machine OEMs, e-Stage Steel+ will streamline the educational curve for new-to-metal clients, enabling quicker and more practical onboarding. This enchancment will enable clients to provide elements with better precision and high quality, whereas decreasing prices, thereby accelerating their capability to scale operations.

Since launching CO-AM, what influence has it had on how producers use 3D printing know-how?

In right this moment’s dynamic trade panorama, platforms like CO-AM are essential for enhancing the effectivity of additive manufacturing (AM) manufacturing workflows. As our clients handle their increasing manufacturing networks, they require a unified resolution that integrates seamlessly throughout all websites, mixing conventional and AM applied sciences successfully.

A key benefit our clients and companions emphasize is the open structure and flexibility of CO-AM. This function permits for easy integration of most well-liked instruments, providing the flexibleness to customise processes to fulfill particular enterprise wants. CO-AM helps each conventional and additive manufacturing capabilities, whereas additionally connecting easily with present manufacturing techniques and quite a lot of manufacturing applied sciences.

Moreover, CO-AM harnesses knowledge to foster steady enchancment, aligning with the lean manufacturing cycle of plan, do, test, and study. This method helps our clients and companions’ ecosystems to pursue sustainable progress and handle dangers successfully.

In your view, what’s the largest problem that the AM trade faces right this moment?

An necessary problem is the necessity for our trade to fulfill the growing calls for of the market successfully, significantly in enhancing the accessibility and cost-effectiveness of 3D printing applied sciences. Central to this imaginative and prescient is the position of software program in decreasing the general prices and complexities related to producing elements through additive manufacturing. There’s a variety of experience and information that we will construct into our software program to information customers and assist bridge the experience hole available in the market.

You might have been a part of the TCT Asia journey proper from the beginning. What has been your spotlight?

We admire that TCT Asia isn’t solely a really necessary platform for us to introduce our newest know-how to China/Asia markets, but in addition a possibility to share our firm values and tradition. In 2021, we stunned guests by planting an actual banana tree at TCT Asia. It was a reference to our “Bananas for Each Girl” undertaking, an initiative began within the African nation of Benin, that goals to enhance diet within the area and supply girls with monetary autonomy.

How do you envision the AM trade progressing over the following decade?

Producers are satisfied of the distinctive advantages that AM gives however after they undertake AM and wish to scale their operations they’re working into every kind of challenges. In different phrases, convincing firms of 3D printing’s advantages is yesterday’s problem. Immediately, the main target shifts from convincing firms to guiding them as they battle to optimize the manufacturing course of and scale as much as quantity manufacturing.

Software program emerges as an necessary participant, injecting intelligence into the method, enabling traceability, and high quality management at each step of the 3D printing journey. Nonetheless, software program alone can not deal with these challenges. It requires collaboration. Our trade must unify to create a secure and harmonious ecosystem with elevated interoperability. Our trade must outline requirements and simplify the adoption course of, making it cost-effective for manufacturing firms to serve their markets with high-quality ultimate elements in excessive quantity.

However we additionally have to collaborate with our clients. To take away present boundaries to allow them to scale up their AM manufacturing. Our trade must make further efforts to handle the challenges they encounter, together with coaching and workforce growth, figuring out new enterprise fashions, and easier-to-use software program and {hardware}.

Register to attend TCT Asia 2024 and go to Polymaker on sales space 8F61. TCT Asia runs from Could 7-9, 2024.