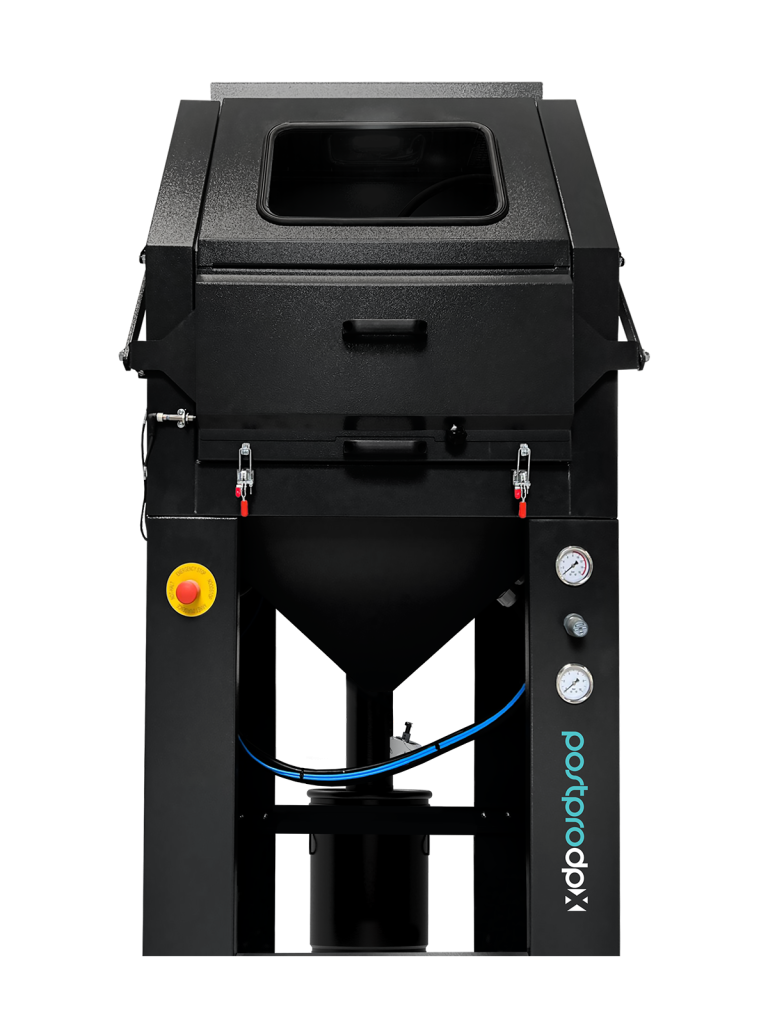

Additive Manufacturing Applied sciences (AMT) has launched its new cost-effective depowdering system, dubbed PostPro DPX, catering to the non-industrial 3D printing market section.

Following the success of its predecessor, the PostPro SFX, which garnered over 100 items offered inside two months of its launch, the DPX guarantees enhanced post-processing capabilities at an reasonably priced value level, says the corporate. Priced at €15,995, the DPX is designed to seamlessly complement the desktop functionalities of the SFX, offering environment friendly post-processing and cleansing options for 3D printed elements. Its compact type issue and budget-friendly pricing make it a super alternative for companies in search of cost-effective but high-quality post-processing choices.

Key options of the PostPro DPX

With dimensions of 985 x 1135 x 1890 mm (W x D x H) and weighing 370 kg, the DPX is flexible and dependable in its efficiency. The PostPro DPX presents a compact and automatic depowdering system tailor-made to effectively post-process 3D-printed elements. A beneficiant basket quantity of 10 liters accommodates varied half sizes whereas guaranteeing thorough cleansing. That includes a user-friendly touchscreen HMI interface, parameter adjustment turns into easy.

Moreover, an ionization unit minimizes static build-up, enhancing operational security. A strong filtration system effectively separates mud particles, sustaining workspace cleanliness. Regardless of its strong capabilities, the DPX maintains a small footprint, making it appropriate for compact areas. ATEX certification ensures compliance with security requirements. For handbook operations, built-in gloves facilitate protected dealing with.

Particularly designed for companies using desktop 3D printing applied sciences, equivalent to these supplied by Formlabs and Sinterit, the DPX caters to environments the place excessive throughput, security, and house effectivity are paramount. Industries like dental, jewellery, and prototyping, which depend on small-scale and desktop printers for complicated and high-quality printing, stand to profit from the DPX’s capabilities.

AMT can also be introducing a particular bundle bundle that features each the PostPro DPX and the SFX chemical vapor smoothing system for a mixed value of €35,995. This bundle goals to offer a complete post-processing answer at a big cost-saving, enabling companies to leverage AMT’s novel applied sciences to streamline their 3D printing processes.

Technical specs of the PostPro DPX depowdering system

| Dimensions | EU | US |

| Exterior Dimensions (W x D x H) | 985 x 1135 x1890 mm | 39 x 44.5 x 74.5 in |

| Weight | 370 kg | 81.5 lbs |

| Capability | ||

| Blast Room (W x D x H) | 850 x 640 x 845 mm | 33.5 x 25.5 x 33.5 in |

| Basket Dimension | Ø450 x 210 mm | Ø17.5 x 82.5 in |

| Basket Quantity | 10 litres | |

| Basket Loading Weight | 10 kg | 22 lbs |

| Door Opening | 645 x 705 mm | 25 x 27.5 in |

| Blast Gun | Single with Ø6 mm nozzle | |

| Filter Cartridge | Single with space of 4 m² | |

| Energy & Pneumatics | ||

| Electrical Configuration | 230V / Single Section / 50 Hz | |

| Whole Energy Consumption | 0.85 kW | |

| Air Consumption | 700l/min at 4 bar | |

| ATEX Classification | Class II 3/-D T125°C | |

What 3D printing traits do the business leaders anticipate this yr?

What does the Way forward for 3D printing maintain for the subsequent 10 years?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business publication or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.